For more efficient pumping of fluids, we should take the pulsating heart as an example, Austrian researchers suggest. In a Nature paper, they present interesting lab results, but large-scale pulsatile pumping of fluids faces significant problems.

The large-scale pumping of liquids accounts for almost 20%of the world’s electrical energy consumption. Clearly, even a small improvement in efficiency will immediately result in a big impact. Researchers at the Institute of Science and Technology Austria (ISTA) argue that pumping liquids through pipelines becomes more efficient by using a pulsatile pumping system. The modus operandi of a beating heart served as their inspiration.

Reducing friction

When fluids flow through pipelines at high speed, they become turbulent. This turbulence causes friction and thus, more energy is required for pumping. Most research into the efficiency of fluid transport focuses on reducing the friction between pipeline and fluid. The oil industry, for examples, applies small amounts of polymers to transport pipelines for this purpose. ‘With this approach, a drag reduction of up to 40 per cent can be achieved,’ says Jerry Westerweel, professor of Aero & Hydrodynamics at Delft University of Technology. ‘Since 1970, this method is used in the Trans Alaska pipeline.’

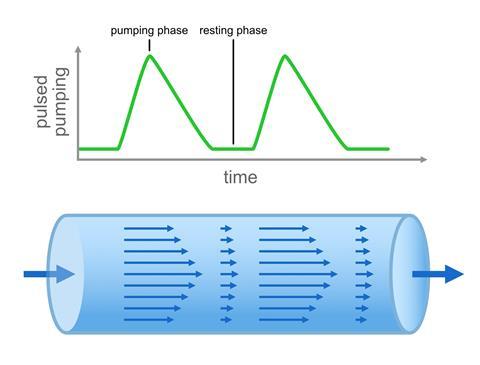

The team at ISTA, based in Klosterneuburg near Vienna, investigated whether varying pump dynamics enables a more efficient flow. The group took the workings of the human heart as an example. After all, evolution has had millions of years to optimise heart function, reasons Björn Hof, who led the research together with first author Davide Scarselli. Normally, pumps provide a continuous flow of fluid. However, the human heart pulsates to keep blood flowing through the veins. It is essential that the blood flow does not create too much friction or turbulence in the veins as this can cause damage to the epithelial cells lining the veins. The researchers were therefore curious to see if such a pulsatile pumping approach would be beneficial for other applications as well.

Resting periods

The team examined water flow in transparent pipelines of different length and diameter. By adding reflective particles to the water, they were able to use lasers to verify whether the flow was laminar or turbulent. The researchers tried different modalities; making the pump accelerate slowly and stop quickly or vice versa. However, it turned out that this actually required more energy to pump the fluid. But by introducing a short resting period between pulses - exactly how a heart works - the turbulence was found to decrease. The flow of water was accelerated and then slowed down, followed by a resting period that made the turbulence die down. These resting periods led to more efficient acceleration of the water flow in the next cycle. Friction was reduced by as much as 27% and energy consumption by 9%.

Water hammer

The ISTA team is confident that their results will enable practical applications in the future, but it will require more development. For instance, pumps are generally not designed to make these pulsating motions, they note in their Nature paper. Westerweel appreciates the underlying idea of the work, but does not think that scaling up to, say, a pipeline for oil transport or liquid gas transport is feasible. He points, for instance, to the occurrence of water hammer. ‘The deceleration of the flow generates a strongly increasing pressure gradient in the tube, proportional to the density of the fluid and the deceleration. A very fast closure creates a very strong pressure wave.’ This effect is also common in everyday life, for example when quickly closing a tap in the kitchen or bathroom. ‘You then hear a loud bang and the pipes vibrate, as if someone is hitting them with a hammer.’ This phenomenon, known as water hammer, can even cause pipes to break, Westerweel explains.

Pressure wave

In the experiments presented in the paper, water hammer hardly plays a role, Westerweel says. ‘The deceleration is 0.2 to 0.5 m/s2. With the limited length of the pipe [1.2 and 7.5 metres, ed.], no significant pressure differences arise.’ But in cyclic transport of oil, he says, it is very different. ‘There, the dynamics of the whole pipe system must be considered at realistic scale. Think of a pipe with a diameter of 20 centimetres and a length of 10 kilometres, through which oil flows at a speed of 3 metres per second. With the same variation of pulsating flow as in this paper, a pressure wave of about 30 bar can be created.’

Westerweel adds another comment. ‘The paper does not consider the fact that the vein wall is elastic. As a result, when there is pulsatile flow, part of the energy goes into stretching the wall, creating a shift between pulsatile flow and pulsatile pressure. This is called the Windkessel-model, which explains the shape of the blood flow and pressure wave. In a rigid tube, this phase difference is not present. Furthermore, the vascular system captures variations in blood flow at high and low heart rates by releasing nitric oxide, which increases the diameter of the blood vessel and thus decreases the flow speed; vascular dilation. With a ten per cent increase in diameter, the speed of blood flow decreases by 40 per cent.’

Nog geen opmerkingen