A 3D printer can make devices entirely from droplets that can be easily redirected or modulated, Chinese scientists show in Nature Chemical Engineering.

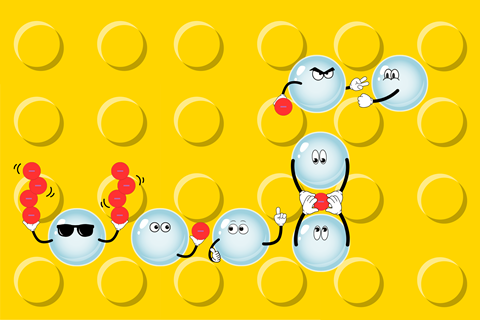

Researchers at China’s South East University in Nanjing have developed a platform that can carry out all kinds of processes in liquid droplets. They use a plate filled with rods less than a millimetre thick, between which a 3D printer (or a researcher) can pipette droplets. Such a drop is about 10 µl and stays in place because of the Laplace pressure of the curved liquid surface. If you place droplets next to it, you get a chain or channel of interconnected droplets that can flow, as shown in the supplementary videos.

Depending on the type of liquid you use, you can make different ‘devices’ without needing a membrane or physical barrier to hold the droplets. For example, the researchers made a membrane-free battery by combining liquid metal, an aqueous solution and an ionic liquid. This allowed a current to flow in the different droplets through redox reactions, and because they are droplets without membranes that do not mix with each other, they can be easily connected in series or parallel.

Another application was a three-droplet chemical microreactor, which allows you to carry out single-pot reactions. You sandwich an ionic liquid between two aqueous solutions. One contains hydrochloric acid, the other sodium borohydride. These two reagents do not mix very well, but by putting an ionic liquid between them, the researchers got around this problem. The ionic liquid contains p-(dimethoxymethyl)anisole. At the interfaces between the liquids, this molecule can react first with hydrochloric acid to form 4-methoxybenzaldehyde, and then on the other side with NaBH4 to form (4-methoxyphenyl)methanol.

But what if you have misplaced a drop in your channel? No worries, you can simply cut the channel with a fluorinated paper and then redirect it with new droplets. The researchers used this fact to demonstrate another application: the enzyme-linked immunosorbent assay (ELISA), a widely used assay that consists of eight steps, including four washing steps.

They immersed the assay in the liquid droplet channels. If you cut the channels, you get microreactors where the reactions can take place. This avoids leaving expensive reagents in the tubes. Then you reconnect the channels with new droplets and the washing steps take place. In this way, they were able to quantify human IL-4 protein in the range of 6.25-200 pg/ml, which is comparable to a standard 96-well plate.

According to the authors, the possibilities are not yet exhausted: in addition to optimising the current devices, they are aiming for more complex chemical reactions with slightly more intensive energy exchange.

Zeng, Y. et al. (2024) Nat Chem Eng 1, DOI: 10.1038/s44286-023-00023-z

Nog geen opmerkingen