A biorefinery waste product can be easily processed into functional powders and tough polymers, Leuven researchers show in ChemSusChem.

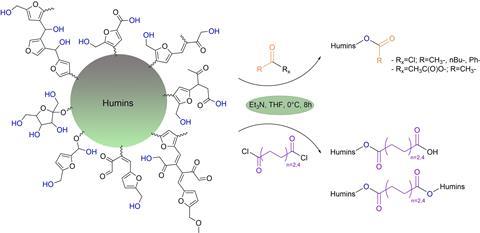

What tar is to petrochemical refining, humins are to the biorefinery. Humins form a black, sticky substance and contain up to 50% of the carbon atoms you start with in a biorefinery, which go to waste. They are formed by side reactions such as aldol condensation or transesterification, resulting in a varying polyaromatic structure with alcohol, aldehyde, ketone and acid groups.

Since it’s impossible to prevent the formation of humins, researchers are trying to find a way to valorise them. Dilhan Kandemir, Peter Van Puyvelde and Anton Ginzburg from KU Leuven have developed a relatively simple synthetic strategy to convert humins into functional materials that are also recyclable.

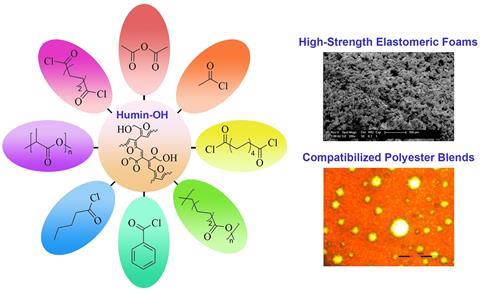

In this study, the researchers focused on the hydroxyl groups in humins and made esters of them with mono- and diacyl chlorides and acetic anhydride. After these reactions, the tar-like substance becomes a powder or - if you use longer diacyl chlorides - a liquid, which makes it much easier to dissolve them in organic solvents such as THF or chloroform and use them as building blocks.

But what if you make humins react with polymers? They tested different polylactic acids (PLAs) and found that if you react them in a 50:50 ratio, you get a strong thermoplastic elastomer. The toughness of the elastomer in turn depends on how many D-enantiomers are present in your PLA: the lower the amount of D-enantiomer, the higher the crystallinity and the tougher the material. Compared to pure PLA, humins-PLA is mechanically much better.

It is also recyclable, the researchers say in the paper. Humins-PLA materials retain their thermoplastic properties when heated and deformed several times. You can also use dissolution recycling, where you dissolve the material and then recover it. In either case, the properties remained very consistent.

In this way, you can add value to the humins, take it out of the waste stream and use it as a building block for other products.

Kandemir, D. et al. (2024) ChemSusChem e202400403, DOI: 10.1002/cssc.202400403

Nog geen opmerkingen