Graphitic carbon nitride is able to replace iridium as a photocatalyst in cross coupling reactions, greatly reducing cost and carbon footprint, according to a study in Angewandte Chemie.

Organic chemists are continuously looking to improve C-C-coupling reactions, as the carbon-carbon bond is one of the most fundamental bond-types in chemistry. Specifically, coupling reactions between a carbon atom with a double bond [C(sp2)] and single bonds [C(sp3)] have become more and more important due to the bond type’s abundant appearance in pharmaceuticals, for example.

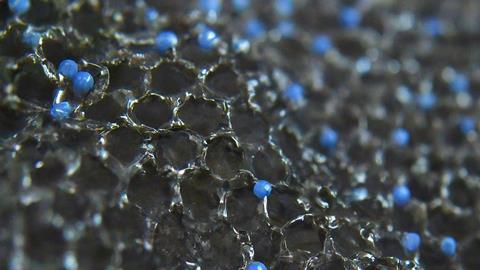

To make these C(sp2)–C(sp3) bonds photocatalytically, you can use a combination of iridium catalyst, nickel catalyst and blue light, which works great. ‘But iridium is five times more expensive than platinum or palladium, and both where and how it’s extracted and refined poses environmental and ethical questions’, says Benjamin Martin, Continuous Manufacturing Network Leader at Novartis. To deal with these concerns, Martin and colleagues from Novartis teamed up with the research group of Timothy Noël at the University of Amsterdam to explore a relatively under-explored photocatalyst that could replace iridium: graphitic carbon nitride (gCN).

Greener chemistry

The collaboration between them started in 2022, Martin recalled. ‘In Europe, there’s not many people in Tim’s league doing photocatalysis and having a deep understanding of the chemical engineering aspects underpinning it.’ Previously, Noël had completed a postdoc at MIT, where Novartis sponsored a decade-long program exploring flow chemistry. ‘That’s how I picked up on his name.’ Like many companies, Novartis has been leaning ever more towards greener chemistry, in which catalysis plays a big role. ‘Photocatalysis can be an especially mild method, since you can explore single-electron catalysis in an accessible way’, Martin explains. ‘That is something we as a company want to apply to chemical development and ultimately to production as well.’

Since a large focussed company like Novartis cannot simply do wide-ranging trial-and-error fundamental research into a new methodology, Martin reached out to an academic partner. ‘We found the idea to work with graphitic carbon nitride in the literature’, says Martin. ‘It seemed pretty ambitious to me, but if it worked, we could do some powerful chemistry with it in a sustainable way’. Tim had already published some other work on graphitic nitrides, so it was a perfect marriage between one partner with the need and one partner with the appropriate research scale.’

Plethora

The researchers started by screening for the optimal conditions needed for the coupling of an aryl halide and an aliphatic carboxylic acid with gCN and nickel catalysts. The team had to overcome competing C-O bond formation providing esters, the natural result from an incomplete loss of carbon dioxide during the desired reaction. ‘Though the paper makes it look smooth, the progress was quite rough at the start’, says Martin. ‘There were three of four months of little progress, when the team finally made a breakthrough, which enabled them to scope out a whole range of substrates . In a way, it opened up a plethora of possibilities.’

‘The nice thing is that we can directly implement Tim’s methodology into our own projects’, Martin continues. ‘We’re already doing photochemistry on a large scale, and these new techniques will apply there for sure, but it will naturally take some time to get it up to the production stage.’

The researchers also looked at the environmental impact this new methodology has. Martin: ‘At Novartis we assess green chemistry according to the total carbon dioxide release, TCR we call it. Some ideas initially sound green, but don’t turn out to be. That’s why we wanted to quantify the impact of our new gCN-method compared to the former iridium method.’ In terms of solvents and reagents, the TCR’s are very similar, but when you look at the impact of the photocatalyst, it’s 491 kgCO2eq/kg for iridium and just 1 kgCO2eq/kg for gCN. ‘Thereby we more than halve the overall footprint by only switching the catalyst. So it’s not just some empty words, but real, quantifiable improvement. All these findings strongly encourage us to continue our collaboration with the Noël group.’

Lukas, F. et al. (2024) Ang. Chem. Int. Ed. e202405902, DOI: 10.1002/anie.202405902

Nog geen opmerkingen