Many pharmaceutical residues and PFAS are released into the environment via our wastewater. Removing these and other contaminants from (waste) water in an environmentally friendly way is a major challenge. A pilot project by Water Authority Zuiderzeeland and Witteveen+Bos using cyclodextrin polymers shows promising results.

Persistent per- and polyfluoroalkyl substances (PFAS) can enter surface water via wastewater and spread further, for example via rivers. Water authorities are struggling to remove these and other contaminants from wastewater at their treatment plants. Today, PFAS are often removed from (waste) water using granular activated carbon, followed by incineration of the contaminated activated carbon at over 1,200 °C - an environmentally unfriendly and inefficient technique.

But alternative, sustainable methods are being developed. A 2023 pilot project at the Zuiderzeeland Water Board’s Lelystad wastewater treatment plant shows that cyclodextrin polymers (CDPs) are potentially rich adsorbents for capturing both PFAS and pharmaceutical residues. The captured contaminants are then destroyed using a ball mill. Witteveen+Bos, the engineering company supervising the pilot project, said in a press release.

Ball mill

Cyclodextrin is a readily available cyclic polysaccharide based on maize starch. By combining the polymer with a specific cross-linking agent, there are many possibilities to achieve substance-specific adsorption.

The US company Cyclopure has used the polymer in what it calls DEXSORB, a reusable filter material with cyclodextrins in the form of selective cups that fit exactly to a drug degradation product or a PFAS molecule.

Once the filter bed is saturated, the material can be regenerated without high temperatures by multiple rounds of refluxing with methanol or ethanol. After regeneration, a mixture of captured PFAS and drug residues remains in the ethanol. This can be thickened and then mineralised using a ball mill, a destruction technique in which very high temperatures can be achieved by high-energy collisions of metal balls of different sizes. The ball mill can therefore remove PFAS in a sustainable way, as it uses less energy than incineration.

Longer contact time required

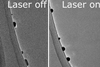

The pilot study in Lelystad showed that at least 70% of contaminants and at least 80% of PFAS can be removed in this way, but according to the US company, an efficiency of 95% PFAS degradation should be possible.

However, the researchers encountered two challenges with the treated wastewater in Lelystad. Firstly, there were too few PFAS present to properly determine the degree of removal. This was successful for other micropollutants. Secondly, the contact time between the water and the adsorbent in the filter column was not optimal in the first pilot project. In order to use the technique on a larger scale, a longer contact time in the filter column is needed to remove the micropollutants properly. As a result, it is still unknown when the desorption equilibrium between the regeneration solution and DEXSORB is reached. Understanding the contact time required in the filter column to achieve maximum achievable desorption can make regeneration more efficient and optimise the regeneration process.

Towards full application

This is what the water boards and Witteveen+Bos want to investigate further at another wastewater treatment plant, the RWZI Dordrecht of the Waterschap Hollandse Delta. The pilot installation arrived at the Dordrecht sewage treatment plant on 25 November 2024. At RWZI, the design of the filter and the backwash regime were optimised to improve the adsorption conditions. It is great that our pilot study in Lelystad has been followed up in Dordrecht,’ says Tiza Spit, process technologist at Witteveen+Bos. It also fits in perfectly with our research into destroying captured PFAS with a ball mill. On to full-scale application!

The first success lies mainly in the sustainable reuse, as the adsorbent used is chemically regenerative. Furthermore, Witteveen+Bos expects that after another successful result in Dordrecht, the next step will be to validate the destruction route with the ball mill on a pilot scale. The use of this technique will not only make it possible to remove PFAS from the water phase in the future, but will also break the PFAS cycle and prevent further accumulation in the environment.

Finally, this new technique is also important to comply with the new European Urban Waste Water Directive, especially for the removal of pharmaceutical residues. The removal of PFAS is then a nice touch. The directive states that both large and small wastewater treatment plants discharging into sensitive water bodies must remove at least 80% of all micropollutants from wastewater by 2045. With current techniques, water authorities are not yet achieving this.

Nog geen opmerkingen