Electric vehicle batteries are notorious for causing uncontrollable fires. Unfortunately, current battery management systems are unable to detect problems in time. Dutch start-up INNER has a solution: a CT machine the size of a battery pack that can do just that.

About 5% of home fires in the Netherlands last year were caused by batteries of electric transportation, tools, tablets, phones or toys. That is almost double that of the year before. It underlines the risks that these batteries pose. This is especially the case for electric vehicle (EV) batteries, explains Mark Crocker, co-founder and Chief Operation Officer of INNER. ‘The key problem is that the batteries contain a lot of highly flammable chemicals and often come in big packs. Even if there is a small local problem, it can lead to a full-scale fire, which is incredibly difficult to put out.’

INNER wants to offer a high-performance battery-pack-size CT machine that is able to detect potential failures of the EV battery in minutes, based on automated AI-based algorithms. ‘We can predict and prevent a thermal runaway weeks or even months before it happens’, INNER’s co-founder and CEO Efrat Avnet Steinberg says.

An upgraded X-ray machine

Currently, there are battery management systems (BMS) built into electric vehicles that keep an eye on battery health, but they are far from ideal. ‘You could compare them to simple hospital tools that can measure saturation, heartbeat and blood pressure, for example’, says Hans Buurman, Co-founder and Chief Technology Officer of INNER. ‘They tell you that something could be wrong, but they do not exactly point to what the problem is. To diagnose cancer, for instance, you need to bring in high resolution imaging, like X-ray- or CT-scanning.’

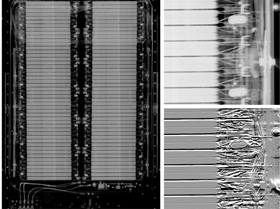

The same goes for batteries. INNER’s CT-machine is based on a typical medical X-ray-scanner, but it has undergone significant upgrades, is bigger and has a modular set-up, which means you can build it in blocks, to adapt to the size of your battery pack. These packs can be as big as three square meters. ‘The technology was originally invented by the Israeli company Cmosaix Ltd.’, Avnet Steinberg says. ‘It consisted of a small detector, and it was launched commercially for the medical market. They decided not to go through with it, although the image quality proved to be superior.’

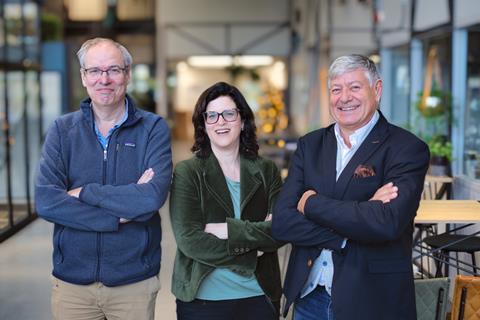

At that time Avnet Steinberg was with the HighTechXL program in Eindhoven. ‘I saw the potential of the CT-scanner for other applications. I reached out to my network and beyond to find the right skilled, entrepreneurial-spirited people to join me on this journey. Eventually a LinkedIn post brought me and my two fellow founders together. We acquired the intellectual property of the technology and started the development.’

That journey led to the start-up INNER in November 2022. At the start, a major part of the development of the CT-machine was about ‘making friends’, according to Buurman. ‘We started collaborating with TNO, who taught us about batteries. Besides that, we learned everything there is to know about X-ray and industrial CT from the Fraunhofer-Entwicklungszentrum Röntgentechnik in Germany. And with the European Joint Research Council we were able to acquire faulty batteries to test.’

Drive-in, drive-out

A challenging part of this R&D period was building the AI-software that analyses the scans of the EV batteries. ‘First we acquired scans of battery cells made with only a small CT-scanner’, Buurman explains. ‘You can simulate these batteries and their defects in a large scanner. But doing so would of course decrease the resolution and the image quality. However, we were still able to get the machine learning algorithms to recognize the faults.’

This year, all efforts were dedicated to advancing the software, with the goal of building a prototype CT-machine in the coming year. It is a mobile scanner that INNER wants to offer as a service to EV battery repair specialists and automotive manufacturers. Next, the team wants to introduce the first drive-in, drive-out chamber to scan battery packs in situ, enabling scans of used cars, and periodic safety evaluations of EV batteries.

‘Electric batteries have phenomenal potential’, Crocker states. ‘I could take a second-hand car EV battery and run my fridge and freezer on it for the rest of my life. At some point, I see them being used in airplanes. But there is no way I would be getting on that plane without a system that guarantees the safety of these batteries. A CT-machine like that of INNER could be part of the solution in the future.’ And that is indeed the company’s mission, Avnet Steinberg adds. ‘We want to make sure that people feel safe to use these batteries in their homes, offices, cars and other forms of transportation, adding to the sustainability impact of longer use and reuse of batteries.’

Nog geen opmerkingen